3 Heating technologies

Figuring out the best heating method which fits customer's purpose, we propose apparatus configurations that make the most use of features of heating technology, such as uniform heating, rapid heating, local heating, and high-temperature heating.

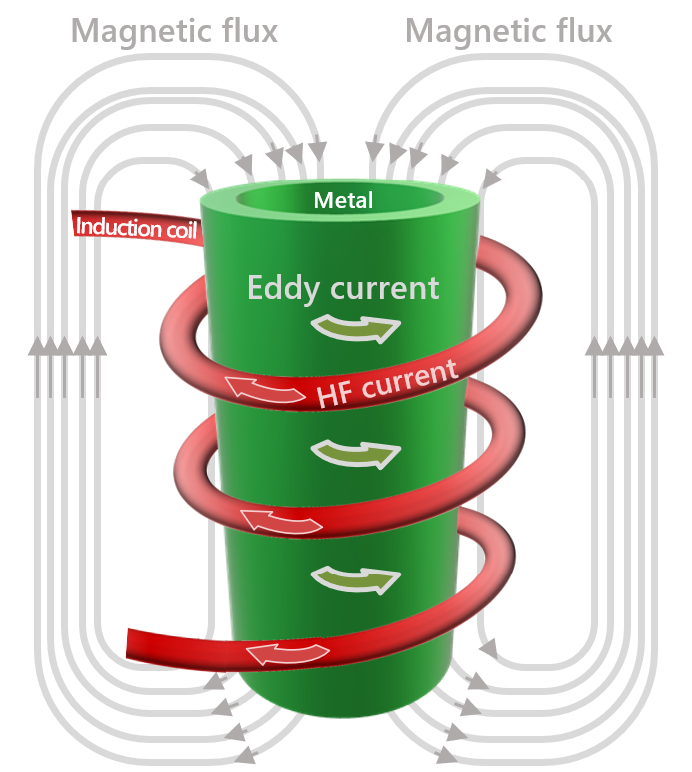

Induction heating

A heating method, of which electric current is induced in a conductive target for the object to heat itself

Metal is placed in a magnetic field generated by passing an alternating current through a coil, and Joule heat is generated by the eddy current flowing in the metal and by the electrical resistance of the metal, causing the metal to generate heat.

※Click here for a detailed explanation of induction heating.

- High temperature/local/rapid heating

- Efficient self-heating

- Contactless heating

Resistance heating

A heating method, which utilizes the principle of heat generation by the electrical resistance of a conductive object when an electric current is passed through it

It uses the Joule heat generated when current flows through an electrical resistance to apply radiant heat to the object.

- Cost and price saving

- Excellent temperature stability

- Wide variety of heater structures (zone heating) )

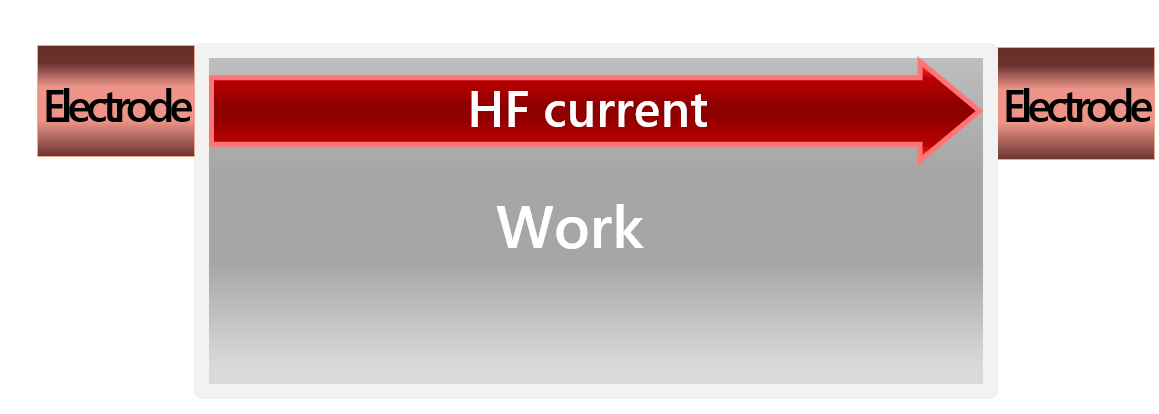

Energizing heating

A heating method, in which a current is applied directly to a conductive object to heat it

By using high-frequency current, the current flows near the work surface due to the skin effect, and the surface can be heated quickly. The heating object must be conductive, so the application would be limited. But it heats the object only, more suitable for quick heat and cool.

- Heat the surface layer only(High frequency energizing heating)

- Rapid heating Direct heating to materials

- Heating power reduces

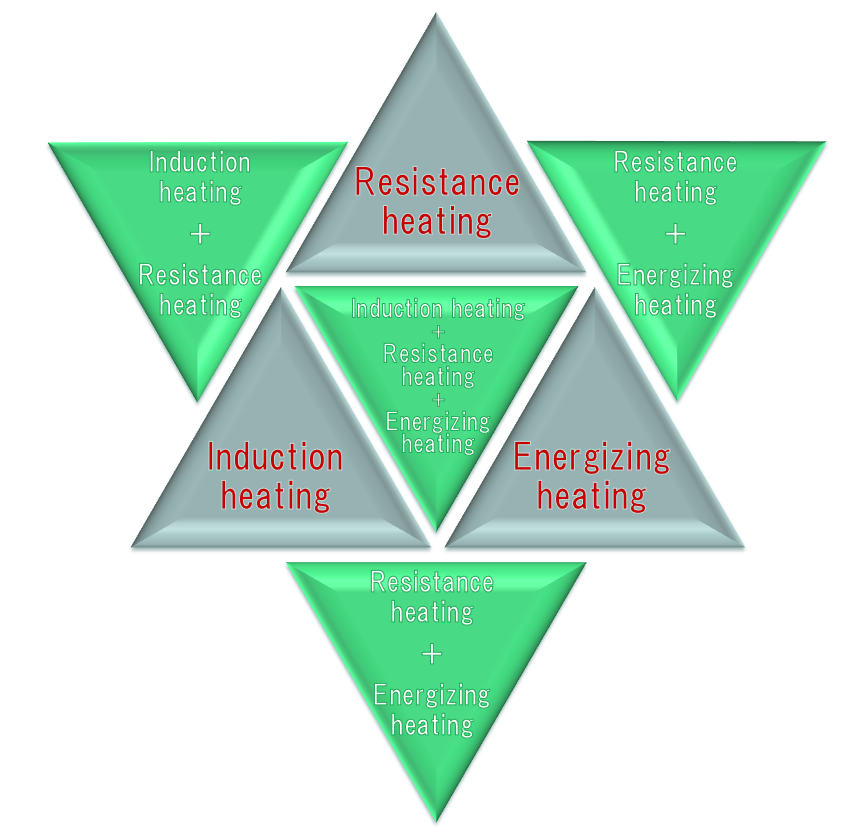

Proposal for hybrid heating

Induction heating + Resistance heating Load lock type CVD apparatus

Induction heating + Energizing heating Hybrid type sintering machine (continuous type) Hybrid type sintering machine (batch type) Multi furnace (sintering, melting,impregnation,hot pressing)

| Technology |