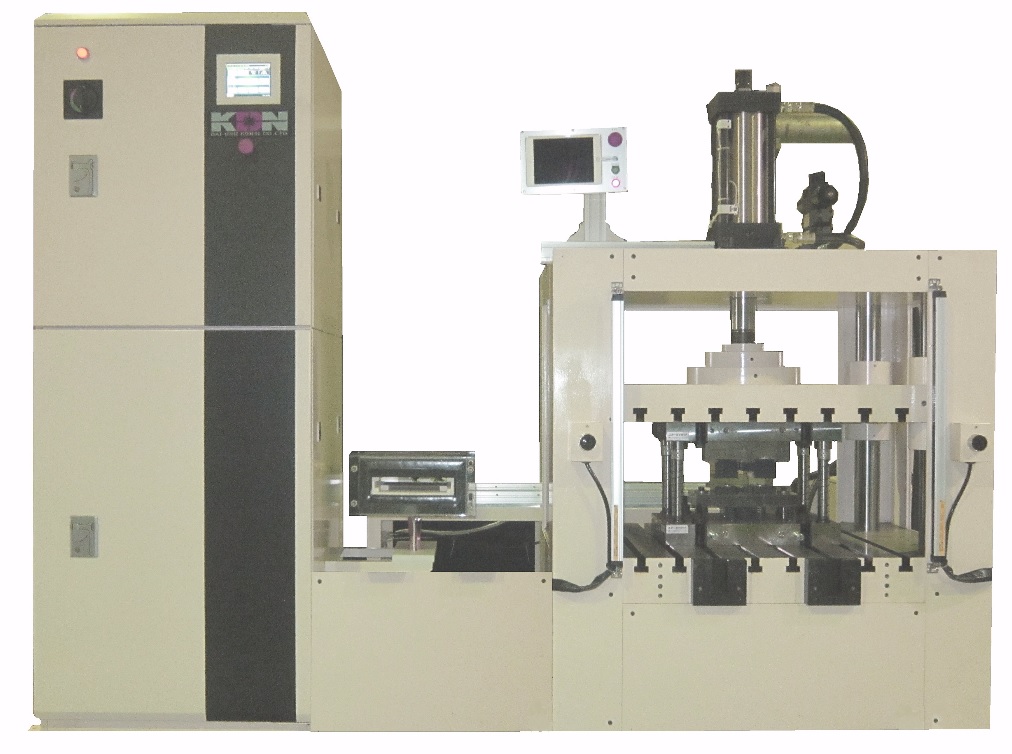

Compact hot stamping system

Compact & Cost-saving

For high tension and CFRTP material

Combining HF heating and servo press

IHS-0200

Description

The weight saving of automobiles and collision safety tends to be improved, and press processing is expected to be a large-scale market.

Dai-ichi Kiden combines proprietary high-frequency heating technology and servo press technology, offering a new system which is overwhelmingly compact, costs lower and shorter in heat treatment time, compared with conventional hot stamp equipment.

"High tensile strength steel sheet" is attracting attention as a material for next-generation automobiles.

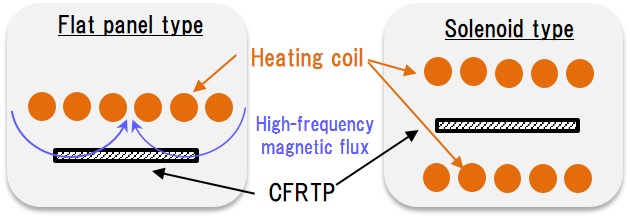

We have designed special coils applicable to hot forming methods and induction heating technology. Heating is performed with energy saving for a short time impossible to achieve by atmosphere heating.

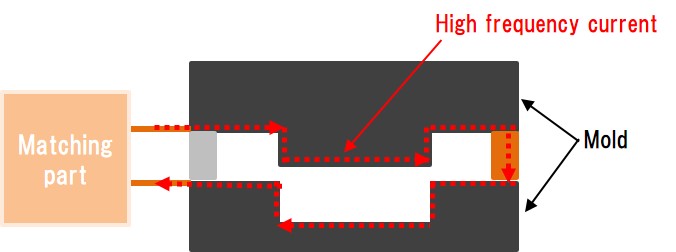

CFRP (Carebon Fiber Reinforced Plastics), which is a light and strong new material, is drawing attention as a substitute material for metals. The mold heating forming technique which could be applied to thermosetting · thermoplastic molding methods, incorporates energization heating technology.

Moreover, heating is carried out for a short time and energy saving by using direct current application technology to material.

Feature

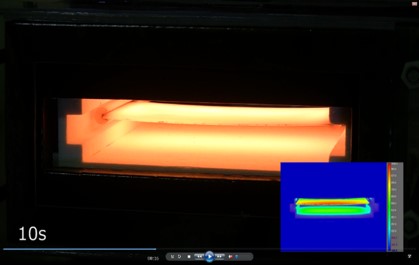

- IH type rapid heating - heating up to 1000 ℃ in about 10 seconds

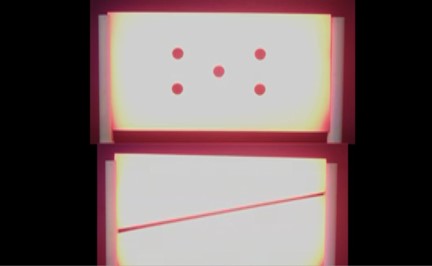

- Heating of hole machining board and trapezoidal plate - Controlling magnetic flux and eddy current to uniform temperature

- Coil shape according to material and process - Control of heat distribution by coil shape

- Heating method utilizing the skin effect - Heat concentrates only on the surface layer due to the penetration depth of the eddy current

Application

- Heat treatment of metallic materials such as high tension, aluminum, titanium, magnesium etc.

- Heat treatment of CFRTP (Carbon Fiber Reinforced Thermoplastic Resin)

|

Heating method |

High-frequency induction heating |

|---|---|

| Heating temperature | 1000℃ (depends on the material) |

| Heating rate | Approximately 10 seconds to 1000℃ |

|

Press |

200kN, Die height 500mm, stroke 250mm |

|

Mold dimensions |

Max. 600mm x 500mm |

|

Transport mechanism |

Electric actuator, stroke 500mm |

|

Work clamp |

Transport speed : 100mm/sec |

| Industrials |