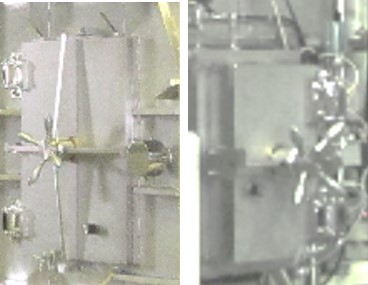

Glove box multi-heating furnace

Heat in the glove box

2 types of heating can be controlled easily

High vacuum and dew point management possible

Automatic control software

HMS-0200G

Description

A glove box heating device that can easily use two types of power sources (high frequency induction heating power supply and pulse power supply). By selecting single / hybrid heating according to your purpose, all heating experiments such as firing, sintering and melting are possible. It can be used as a multi-experiment furnace to control pressure and distance with a servo press to perform hot pressing, hot working, unidirectional solidification, etc.

The power supply is equipped with 2 types of induction heating and pulse current heating, so that 3 types of heating can be selected: ①high frequency induction heating ②pulse current heating ③hybrid heating combined with both. Hybrid heating can be performed while changing the ratio of induction heating and pulsed heating.

The atmosphere inside the pass box attached to the glove box can be controlled independently.

As an optional specification, it supports 10-4Pa level high vacuum and dew point management. Equipped with an electric servo press, pressurization tests can be performed while finely controlling pressure and distance. Since our automatic control software is installed, the software can be changed according to your purpose.

Feature

- Heating in the glove box is possible

- High vacuum specification up to 10-4Pa

- Can continue the experiments in a clean environment

- 3 types of heating methods (high frequency, pulse current, hybrid)

- Pressure control and distance control are possible

- Power control and temperature control are possible

- Collect and save experiment data on PC

- Automatic control software designed by KDN

Specification

| Heating method | High-frequency induction heating + pulse current heating |

|---|---|

| Heating temperature | 1700℃ |

| Heating rate | 100℃/min |

| Chamber | Glove box + pass box |

| Atmosphere | Inert gas atmosphere after vacuum |

| Heating control method | Power control or temperature control |

| Press method | Servo press 200kN |

| Temperature measurement | Thermocouple or 2 color pyrometer |

| Optional |

Ultimate vacuum 1×10-4Pa, high temperature heating up to 2500℃, Hydraulic press (Pressure control), Dew point control (-75℃) |

| Industrials |