Hybrid type sintering machine (batch type)

New Hybrid Sintering

Compact fit for R&D

SiC RF Induction Heating+Pulsed power+Servo press

HMS-0100B

Description

In combination with high-frequency heating and plasma discharge heating, it can do uniform sintering by a servo press control of the punch, after being heated in a few minutes up to a high temperature range.

A shorter sintering time compared to the hot press, is suitable for research purposes also in mass production equipment.

Feature

- The speed of sintering process is enhanced by a hybrid heating system in combination with a pulse current and HF induction

- Possible to control the precise pressure and pressing position by the high-performance servo press

- The monitoring of the torque management and work resistance value of the press, can be delicate adjustment of sintered density

- Heating recipe and atmosphere in conjunction with the press control by the program

- A combination of high-frequency induction heating allows for lower temperature and a shorter time period procedure without the need for bounding materials

Technology

Hybrid heating & precise press control

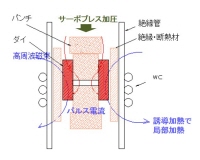

RF Induction heating, Electric plasma heating make quick temperature increase to high temperature zone. Servo press provides precise sintering control.

Originally designed Continuous Sintering Process

Continuous sintering process helps ensure high productivity.

8 stations(8 cartridges) are provided in the continuous sintering system. 8 different types of sintering processes are available to be set individually which will shorten test time in laboratory.

Sic power module help RF Induction heating to save cost of energy consumption.

-

Principle of hybrid sintering

-

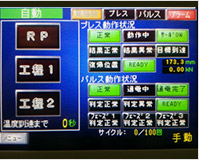

Easy operation by touch panel

-

Precise control by servo press

Specification

| Target size | Max. φ20mm |

|---|---|

| Heating temperature | Pursed + HF induction, 1500℃ |

| Sintering pressure | Max. 100MPa |

| HF power supply | Max.output 20kW, frequency 13kHz |

| Pulsed power | Max. output 15V、2000A |

| Industrials |