Hot stamping

Dai-ichi kiden is on applying the own high-frequency heating technology and servo press technology to brand-new Hot and Warm forming apparatus, for development of lightweight material such as "High Tensile strength Steel", "CFRP", "magnesium alloy" process quick and spot heating by RF induction heating.

We aim that this development would build up the new technology of energy saving and space saving to reduce the use of energy to a minimum, with overwhelmingly compact and short treatment time.

Hot forming

In this development, we adopt the induction heating which is difficult in being used in the high-tensile steel area.

Taking advantage of the rapid response which is the benefit of induction heating, to achieve a rapid heating and spot heating, it will apply the clean electrical energy in every process.

Warm forming

By using a high-frequency electric heating technology, it can do the electric heating to the mold of such as magnesium alloy and titanium alloy and CFRP (heat curing and thermoplastic) forming. Is precise temperature control is achieved in a short period of time in this development, we will apply the short-time and energy-saving heating to every process.

Forming test

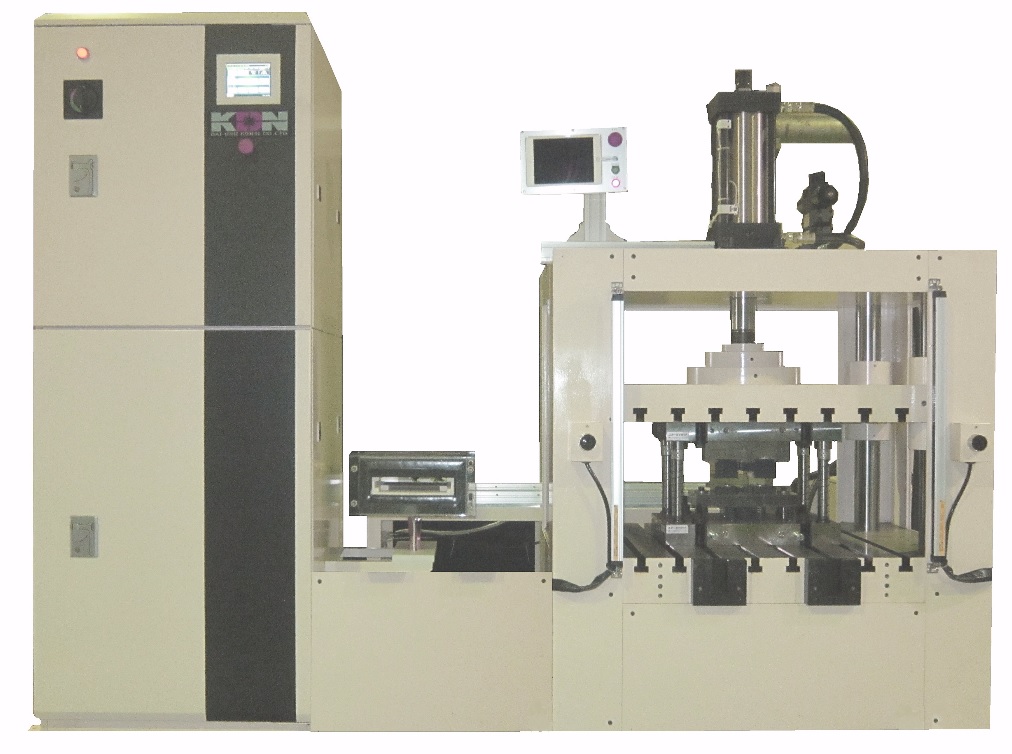

Development equipment

| Development |